For children across Vermont whose bodies require support for independent movement and mobility, help may be arriving in the form of the humble hoverboard.

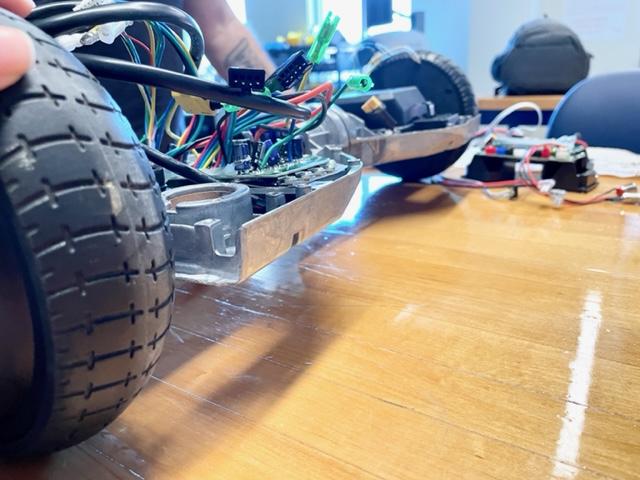

By combining the basic structure of a hoverboard with in-depth knowledge of both movement-related disabilities and DIY kits, UVM students are prototyping a new way for Vermonters to build custom power mobility units for children.

The term “power mobility” refers to a class of motorized carts, scooters, or wheelchairs. The user then steers the device using a joystick or button. And when it comes to children’s power mobility, those devices are typically modified toy ride-on cars or power wheelchairs.

And there’s a huge need for them among Vermont’s population of young children experiencing movement-related disabilities.

“We see many children whose bodies move in ways other than the world typically expects,” explains Tamra Yandow, coordinator of the Vermont Early Mobility Project at the UVM Center on Disability and Community Inclusion. “We see children from all over the state who would benefit from a means of independent mobility. We know access to mobility can improve developmental skills in many areas, and we want to be able to provide affordable mobility to as many young children as possible. Unfortunately, the options for child and family friendly vehicles are extremely limited in this country.”

Because power mobility units must be built by a local team, hold up to toddler driving skills and be customizable as they grow, one aim of the project is to come up with a kit that’s easy to build and is more sustainable and easier to repair than earlier models.

This year, the VT Early Mobility Project is collaborating with the UVM Center for Biomedical Innovation (CBI) to build a prototype vehicle. This CBI project includes both engineering and physical therapy students, an unusual collaboration at the University. This allows the project to combine engineering know-how with fine-tuned knowledge of what works best for children with disabilities. “It’s hugely exciting to have these two programs collaborating, and provides a unique learning opportunity for the students,” says Yandow.

Lea Meibauer, a second-year graduate student in the Department of Rehabilitation and Movement Science, is part of the build team. “Myself and the other physical therapy student, we have that knowledge of what a child, for example with cerebral palsy, looks like. And we can bring that into the conversation with engineering. We can say we need to have a seat, for example, that can tilt. It just needs to be adaptable to the child’s specific needs.”

Mike Rosen is the interim director of the CBI, and is providing oversight and support for the prototyping. He explains that for the engineering center, this project is part of a much larger vision for how the University can apply know-how and cross-campus collaboration in providing real-world functional healthcare support across the state. “For us, this is really the theme of the CBI: create new technologies, new systems, new devices, new apps that serve people who are remote from huge healthcare centers like here in Burlington.”

While engineering is a largely creative science, in this case, solving the problem of where to begin building proved relatively easy, as some of the engineering students working on the build immediately thought of the parallels between the basics of power mobility geared for disability, and a form of campus transport near and dear to their hearts: the hoverboard.

This very practical slant on problem-solving has helped Meibauer understand more about the creative aspects of engineering. “Myself and the other physical therapy student, we just tell them what we’re thinking, and they draw it out, then we use everyday materials, like wood, or hoverboard wheels! We’re using not very complicated things to create this object that can have a real impact.”

The quality of that collaboration and the ways in which it has sped up the design process has delighted Rosen. “One of the engineers will say, oh, this joystick looks perfect for a control for the kid using this thing. And then one of the physical therapy students will say, ‘Well, that’s only if it’s this kind of cerebral palsy. What if it’s a different type altogether?’ There’s this ongoing organic, continuous cross-disciplinary education going on. It’s working out beautifully.”

Both Meibauer and Rosen report that the biggest challenge facing the project so far has been both scheduling team meetings, and negotiating disruption to the supply chains.

The project hopes to have their first model finished by the end of the Spring 2022 semester.

Says Rosen: “You don’t really know whether you’ve succeeded until it’s in use. So I want to see this project out there in trials. I want to see the instructions written. I want to see a study in which we hand over the instructions and walk away and wait to see how it goes, and what people tell us.”

But for Meibauer, the end goal is simple.

“If it is as adaptable as it can be for any child, no matter what their disability,” she says, “then I think that we won. We accomplished what we set out to do.”